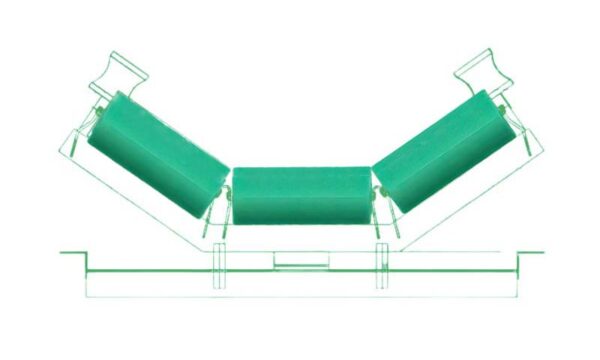

Trough Training Idlers

- Description

Description

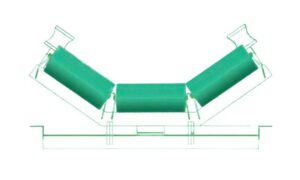

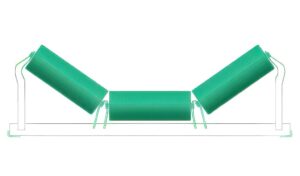

Trough Training Idlers are designed to automatically guide the conveyor belt back to center alignment on the carrying side, helping to prevent mistracking, edge damage, and material spillage. Rite Idler’s training assemblies use a pivoting frame and friction-based guidance system to detect and correct belt drift before it causes performance or safety issues.

These training idlers are ideal for long or misaligned conveyors, load zones, and other critical areas where belt wander is common. Built for durability and smooth operation, they integrate seamlessly into standard frame setups without requiring complex adjustments.

Trough Training Idlers are available in single-direction or bi-directional models and are compatible with CEMA C, D, and E duty ratings. All rolls are manufactured with CNC-machined steel end caps, deep-groove ball bearings, and Rite Idler’s 7-component sealing system to ensure long service life, reliable tracking, and minimal maintenance.

Applications:

-

Long conveyor runs prone to drift

-

Load zones with uneven material flow

-

Areas requiring active belt realignment

Key Features:

-

Pivoting frame adjusts to belt movement for real-time alignment

-

Available in one-way or two-way (bi-directional) tracking options

Trough Training Idlers help maintain proper belt alignment by automatically correcting belt drift on the carrying side. Ideal for long runs or load zones, these pivoting frames guide the belt back to center, reducing spillage, wear, and downtime—without the need for manual adjustment.