Our Bearing Assembly

and Shaft Design

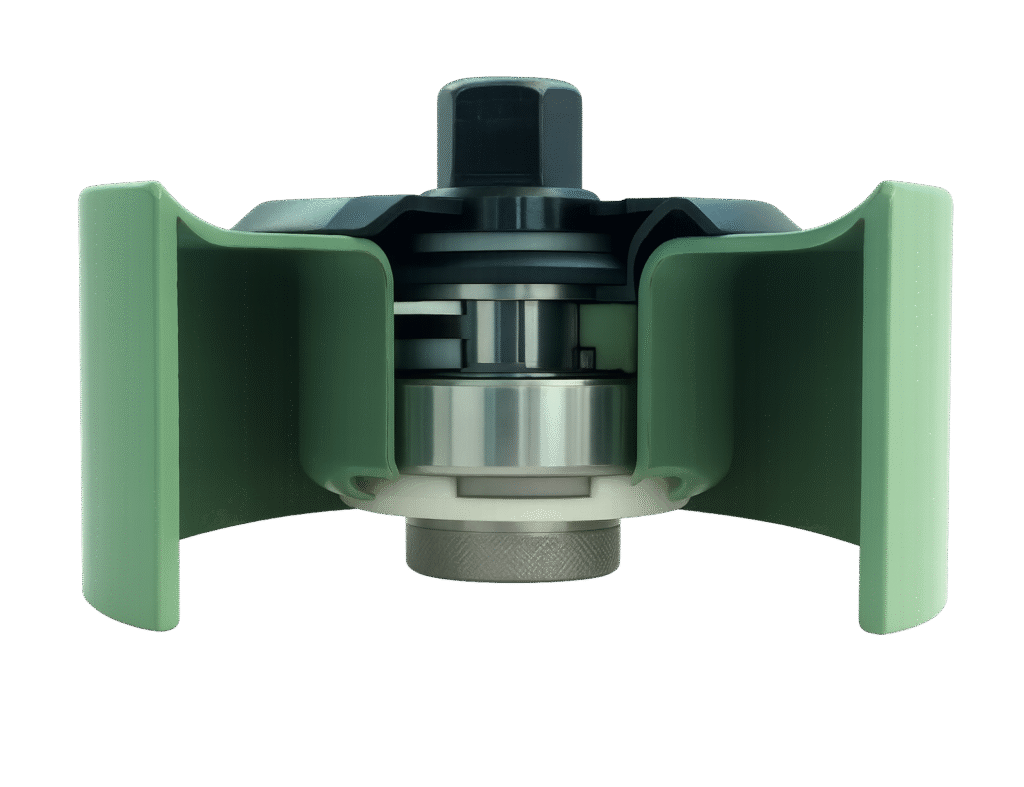

The bearing is the single most critical component in any idler. Bearing seizure directly results in roll failure. At Rite Idler, our design approach prioritizes bearing protection to extend service life and reduce conveyor maintenance.

Precision-Machined Endcaps & Shafts

Our endcaps are stamped from steel coil through a multi-stage process with an increased draw depth to allow space for complex sealing integration.

We go the extra step by precision-machining both the outer edge and the inside of our endcaps.

Machining the outer edge of our endcaps guarantees an exact fit with the roll shell, improving TIR of the roll and assembly consistency.

The end of our shafts are precision - machined to provide a precise interference fit with the inner bearing race.

Shafts plugs are also machined to eliminate variation and provide an ideal interference fit with the inner bearing race.

Comprehensive Sealing System

Grease-Filled Cavity

The entire bearing cavity is pressure injected with high-quality grease, creating a permanent lubrication environment and an internal barrier against contaminants.

Deep Groove Ball Bearings

- Open-faced deep groove ball bearings give access to the full grease cavity.

- No maintenance or adjustment necessary.

- Chosen bearings exceed specified CEMA ratings.

Protective Flinger and Deflector Cap

- A flinger deflects material outward from the rotating roll face.

- The external black deflector cap, branded with "Rite," functions as a dust shield, physically blocking fine debris and moisture from entering the roll housing.

Outer Seal Arrangement:

Includes four sealing components seals and a nitrile rubber V-ring forming a grease-filled cavity to stop external material ingress.

Adaptable Shaft End Configurations

Rite Idler shafts are made with drilled and tapped ends into which we install a wide range of precision machined shaft ends. This provides a roll that exactly matches the dimensions of your current rolls, ensuring an accurate fit into your existing frames regardless of who made them.

Rolls over 13 inches: Use a composite shaft consisting of a hollow pipe matched with solid precision-machined plugs. This design results in a stronger shaft with less deflection under load.

Rolls under 13 inches: Use shafts made from solid bar, with the same drilled and tapped ends to accommodate the same precision-machined shaft-ends

Through precision machining, sealed grease cavities, multi-component sealing systems and adaptable shaft designs, Rite Idler delivers unmatched bearing integrity and conveyor reliability for the most demanding operating environments.

Need help choosing the right fit? Use our Rolls & Frames Measuring Guide or submit your dimensions using Our Forms —our technical team is here to help.

Can’t find what you’re looking for? Contact us to explore additional options.

Replacement Rolls

Replacement Rolls Bearing & Shaft Design

Bearing & Shaft Design