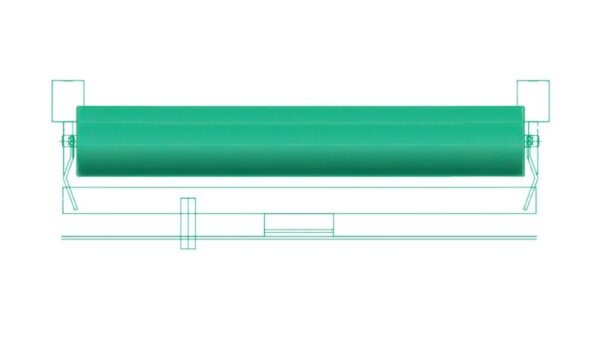

Return Training Idlers

- Description

Description

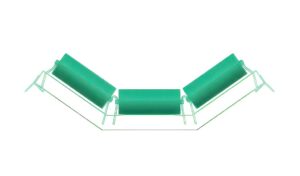

Rite Idler’s Return Training Idlers are designed to correct belt misalignment on the return side of the conveyor, helping prevent edge damage, material spillage and excessive wear. These self-aligning units pivot as needed to guide the belt back to center, improving overall belt tracking and reducing the need for manual adjustments. Return Training Idlers are essential in systems prone to belt wander caused by variable loading, uneven tension, or off-center feed conditions.

Built with CNC-machined steel end caps, deep-groove ball bearings and Rite Idler’s standard 7-component sealing system, these training idlers are made to perform reliably in tough operating conditions. The swiveling frame is designed for consistent, responsive movement without adding drag or compromising structure life. Return Training Idlers are a dependable solution for improving tracking performance and reducing downtime.

Key Features:

-

Self-aligning design for automatic belt centering

-

Ideal for preventing belt edge wear and spillage

-

CNC-machined end caps for precise bearing support

-

Deep-groove ball bearings with full-cavity grease fill

-

Available in CEMA C, D, E duty ratings

Return Training Idlers automatically guide the belt back to center, reducing misalignment, edge damage and material loss. With a durable, low-friction design and Rite Idler’s signature bearing protection, they keep systems running efficiently and reduce maintenance requirements.