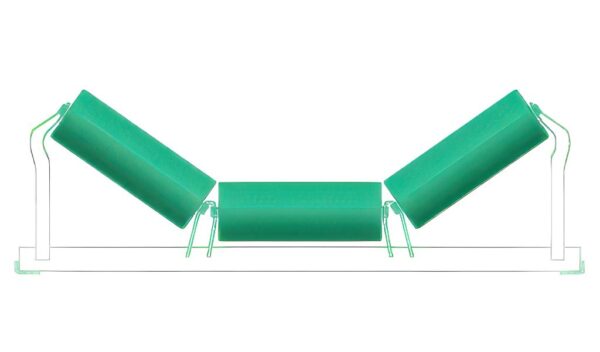

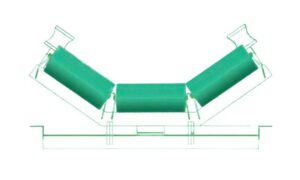

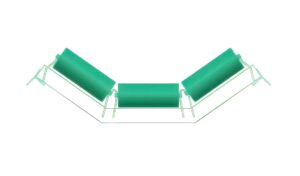

Troughing Idlers

- Description

- Additional information

Description

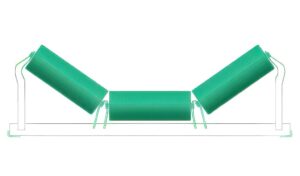

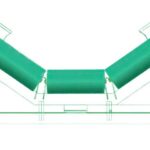

Rite Idler’s Troughing Idlers support the loaded side of the conveyor belt, forming a consistent trough that helps contain bulk materials and guide the belt efficiently through the conveying system. These idlers are used across industries ranging from aggregates to heavy mining.

Each roll includes precision-machined end caps and is protected by Rite Idler’s signature 7-component sealing system for extended bearing life and minimal maintenance.

Key Features:

- Offered in CEMA C, D, E, and F+ duty ratings

- Precision-machined end caps for optimal bearing fit

- Full-cavity grease injection in deep-groove ball bearings

- • 7-component sealing system offers maximum contamination protection

- Coating options: rubber, urethane, ceramic

Troughing Idlers are a critical part of the load-carrying side of your conveyor system. With rugged components and dependable sealing, Rite Idler provides belt support that minimizes spillage, maximizes service life.

Additional information

| 01 | Staggered (Offset) Trough Idler |

|---|---|

| 02 | Inline Trough Idler |

| 03 | Variable Trough Transition Idler |

| 04 | Impact Trough Idler (Rubber Rolls) |

| 05 | Trough Training Idler for Reversible Belt – No Decking |

| 06 | Trough Training Idler for Reversible Belt- Decking |

| 07 | Trough Training Idler – No Decking |

| 08 | Trough Training Idler – Decking |

| 09 | Unequal Length Rolls Trough Idler |

| 10 | Unequal Length Rolls Trough Impact Idler (Rubber Rolls) |

| 11 | Unequal Length Rolls Trough Training Idler – No Decking |

| 12 | Unequal Length Rolls Trough Training Idler – Decking |

| 13 | Unequal Length Rolls Trough Training for Reversible Belt – No Decking |

| 14 | Unequal Length Rolls Trough Training for Reversible Belt – Decking |

| 15 | Picking Idler |

| 16 | Picking Impact Idler |

| 17 | Picking Impact Idler with Steel End Rolls |

| 18 | Picking Training Idler |

| 19 | 2-Roll Retractable Trough Idler |